The Most Logical Choice for Smarter Spaces – GrowSpace

Hello, this is FREEGROW.

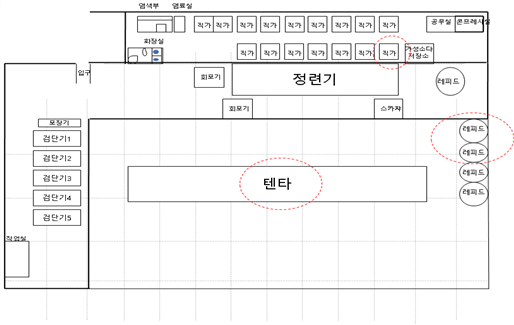

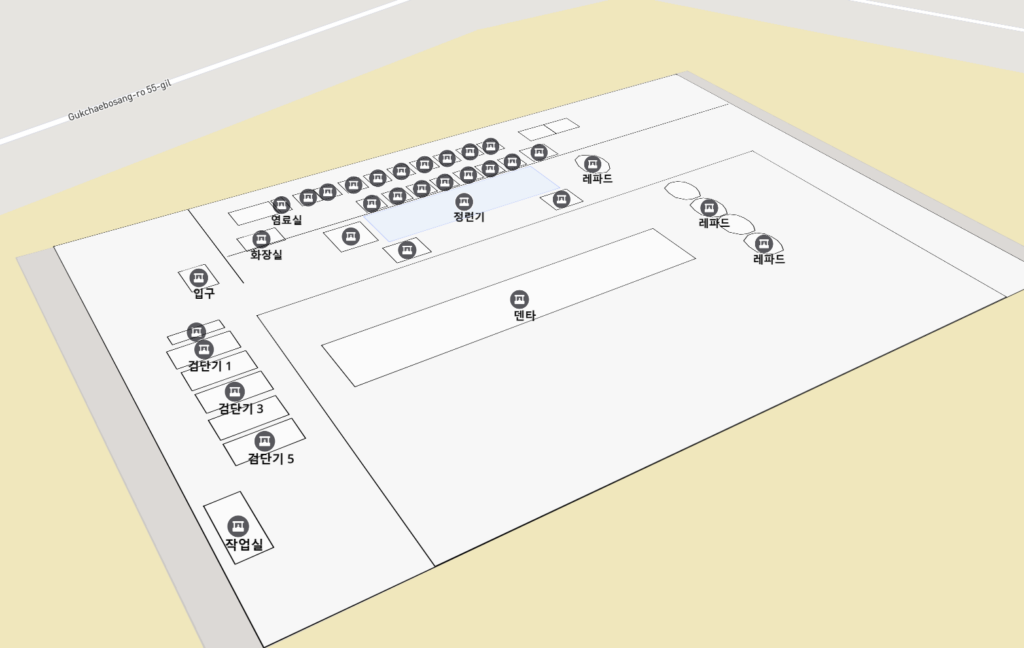

Today, we introduce a case study of how GrowSpace’s UWB indoor positioning solution was implemented in a dyeing factory in Daegu.

Dyeing factories involve complex processes with multiple workers, making indoor positioning solutions essential for this industry.

GrowSpace provides a web-based smart mapping service that allows managers to monitor operations in real time while ensuring workplace safety.

Additionally, it enhances productivity by enabling real-time tracking of materials and equipment.

In this post, we will explore how GrowSpace’s UWB solution was deployed in the Daegu dyeing factory, detailing the implementation process and its outcomes! 😊

Why Smart Mapping is Essential for Dyeing Factories

Smart mapping goes beyond simply providing location information; it is an advanced system that offers personalized data and interactive features.

Dyeing factories have a vast layout with scattered equipment and materials, where workers must manage complex workflows.

Traditional paper-based maps are insufficient for efficient asset and workforce management, but

GrowSpace’s smart mapping provides precise location tracking and optimized navigation even indoors, significantly improving both operational efficiency and workplace safety.

In particular, the smart mapping solution implemented in this dyeing factory provides accurate navigation and optimized movement paths even in a complex layout.

As a result, it improves operational efficiency while reducing the risk of workplace accidents.

UWB Real-Time Location Tracking: Implementation and Live Usage!

Prepared UWB Kit Components

- Approximately 20 anchors

- Approximately 30 tags

These components work together to enable precise location tracking and data management within the dyeing factory.

Installation and Configuration Process

Upon arriving at the factory, we unpacked the GrowSpace UWB kit and began setup.

Anchor Installation

We set up the prepared anchors on tripods and connected them to portable batteries to perform an initial positioning test. This step is essential to ensure the equipment functions correctly and to calibrate optimal placement for the testing environment.

Coordinate Calibration

Each anchor has a unique location. After setting up the reference coordinate system, we measured the X and Y coordinates (in meters) for each anchor and registered them in the GrowSpace App. This step ensures accurate mapping of location data.

Device Registration

Registering devices is very simple!

You can register devices using the unique Serial Number and authentication key provided at the time of shipment.

Additionally, using the QR code scanning feature allows for quick and easy device registration.

To summarize, connect the device to power, search for the device in the app, and then scan the QR code attached to the back for easy authentication and registration. If you encounter any issues, feel free to contact GrowSpace, and we will quickly assist you!

Registered devices store data on our company server, allowing real-time location tracking.

This data is available through a web-based system, allowing easy access across Android, iOS, MacBook, and Windows devices.

This data is accessible through a web-based system, making it easy to view on Android, iOS, MacBook, and Windows devices.

The following video shows a real-time dashboard displaying the movement of installed physical and personnel tags, along with anchors.

Easy and Simple Implementation

GrowSpace offers a UWB Kit that can be self-installed, along with a professional installation service.

It provides GPS-level precision, enabling real-time tracking of people, objects, and autonomous robots.