Manufacturing, Now ‘Location Tracking’ is the Key to Competitiveness.

Hello! This is FreeGrow.

As the manufacturing industry rapidly evolves, is your company also working to enhance productivity, implement automation, and maximize operational efficiency?

In this transformation, real-time location tracking technology has become an essential element of smart factories. However, traditional GPS, Wi-Fi, and Bluetooth-based tracking technologies have clear limitations. These technologies suffer from low accuracy, weak signals in indoor environments, and security vulnerabilities. Additionally, they struggle to effectively provide real-time data.

The technology that can solve these challenges is UWB (Ultra-Wideband). UWB provides an innovative solution by offering high-precision real-time tracking of workers, equipment, and materials. Let’s explore why UWB is essential in manufacturing and how it can drive smart factory innovation.

Why UWB is Essential in Manufacturing – Maximizing Productivity with Real-Time Location Tracking

In manufacturing plants, the movement paths of workers, equipment placement, and material location directly impact productivity. Even minor adjustments can affect production speed and lead to unnecessary costs.

For example,

- Production slows down if workers take too long to locate required parts.

- If factory equipment layout is not optimized, workers and logistics equipment move inefficiently.

- If materials are not in their designated locations, there is a higher risk of production delays.

To resolve these issues, an accurate, real-time location tracking system is essential.

UWB technology plays a critical role in this. By leveraging UWB,

- Worker movement paths can be analyzed in real-time to reduce unnecessary movement.

- Equipment and raw material locations can be automatically tracked to prevent production delays.

- Integration with AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) allows for fast and precise material transportation.

Ultimately, UWB-based location tracking systems enhance manufacturing productivity and reduce operational costs. Efficient factory operations require highly precise indoor tracking technology, and UWB is the ideal solution.

Factory Automation & Logistics Optimization – Completing the Smart Factory with UWB

As the transition to smart factories accelerates, AGVs (Automated Guided Vehicles), AMRs (Autonomous Mobile Robots), and forklifts have become essential for logistics automation. However, automated logistics systems require precise location information for seamless operation, and this is where UWB technology plays a key role.

Global Companies Are Already Utilizing UWB

Many global manufacturing companies have adopted UWB technology to build smart factories. As factory automation and real-time location tracking become crucial, leveraging accurate location data to enhance productivity and optimize logistics is now a key competitive factor for businesses.

Here are some representative companies:

Tesla – Utilizing UWB to establish autonomous mobile robots (AMRs) and logistics automation systems within its factories. This allows materials to be automatically transported via optimal routes when needed, ensuring efficient production workflows.

Boeing – Implementing UWB in aircraft assembly plants to track workers and tools in real-time, optimizing workflows and reducing inefficiencies in the assembly process.

Volkswagen – Enhancing AGV (Automated Guided Vehicle) operations and automating inventory management to efficiently manage material flow within factories using UWB technology.

As seen above, UWB is rapidly becoming a crucial technology in manufacturing, making it an essential consideration for companies aiming to operate smart factories.

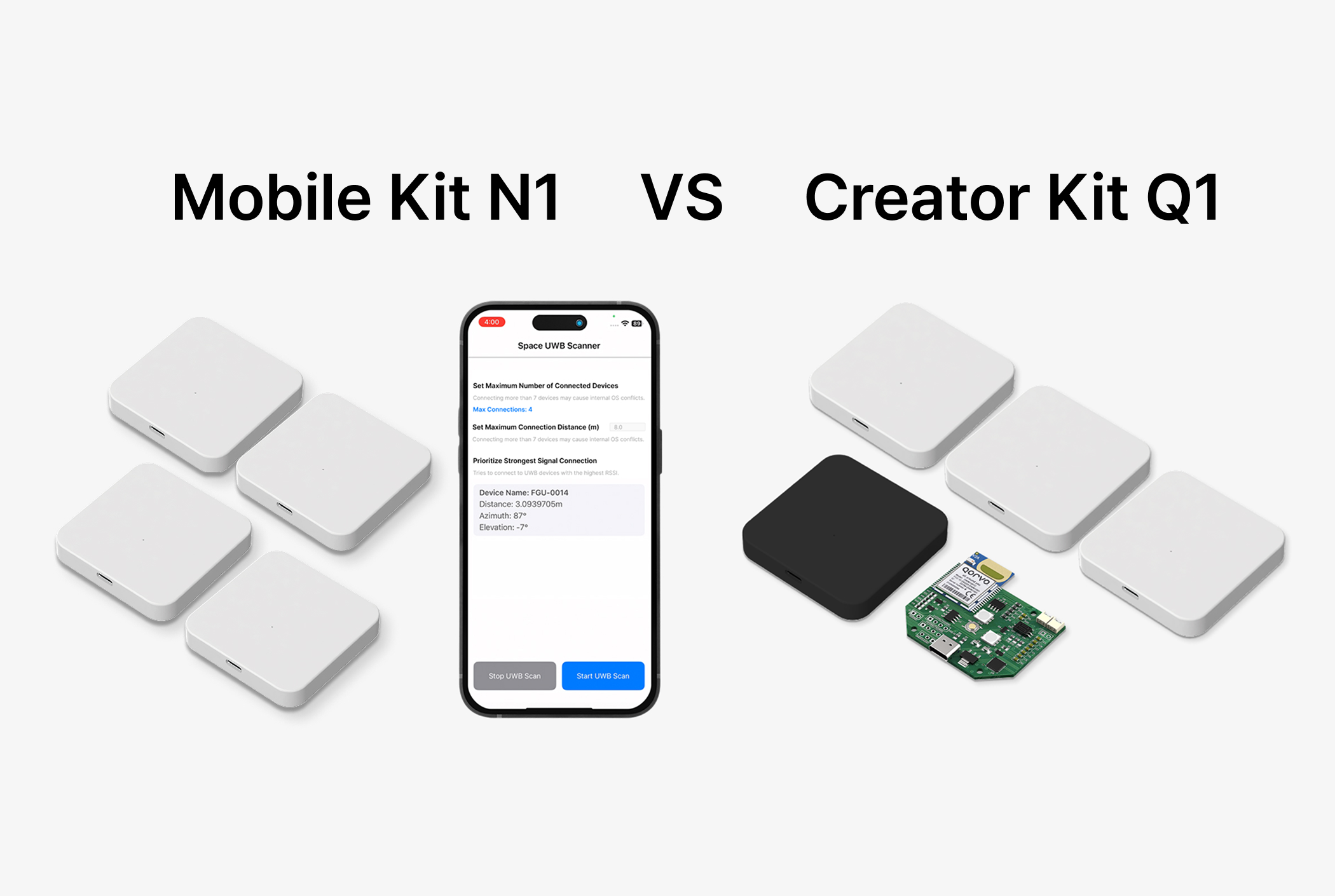

GrowSpace’s UWB Solution – A Differentiated Advantage

As indoor location tracking technology becomes increasingly important in manufacturing, GrowSpace offers a customized UWB solution that supports factory automation and logistics optimization.

Beyond simple location tracking, our system is designed to maximize productivity and operational efficiency. Here’s what makes GrowSpace’s UWB solution unique:

1. Ultra-Precise Real-Time Location Tracking

In manufacturing, accurate real-time tracking of equipment, materials, and workers is crucial. GrowSpace’s UWB solution provides precision within a 10–30 cm margin of error, optimizing material flow and eliminating production bottlenecks.

With real-time visibility of worker and equipment locations, efficient process management becomes achievable.

2. Easy and Fast Implementation & Maintenance

If a new technology is incompatible with existing systems, adoption can be challenging. GrowSpace’s UWB solution seamlessly integrates with IoT, MES (Manufacturing Execution System), and ERP (Enterprise Resource Planning) platforms, ensuring smooth implementation.

Additionally, installation is simple, and maintenance is user-friendly, allowing companies to quickly deploy and utilize the technology.

3. Strong Security & Stable Operation

Wi-Fi and Bluetooth-based tracking technologies have security vulnerabilities and are prone to signal interference. In contrast, UWB is highly resistant to signal tampering and minimizes data breach risks. GrowSpace leverages these advantages to provide a secure and reliable location tracking system for manufacturing environments.

Now is the Best Time to Adopt UWB

If you have any questions or want to learn more about UWB adoption and factory automation, feel free to reach out.

GrowSpace is always ready to make your manufacturing environment smarter and more efficient.

With expert consulting and rapid support, we will provide you with the optimal UWB solution.