Hello, this is Freegrow.

When you prepare a capstone design or graduation project, you may think,

“Maybe we can save money by building the module ourselves?”

Most of you have probably thought about this at least once.

The case I will share today also started with that idea.

A university student project team wanted to build a UWB-based pedestrian tracking system.

They tried to assemble the DWM1000 modules by themselves and run tests.

But the result was not as easy as they expected.

⚡ First Attempt – Crowtail DWM1000 Module

The first choice of the students was the Crowtail DWM1000 module.

At first glance, it looked simple.

It had pin headers to connect directly with Arduino.

They thought, “If SPI communication works, distance measurement will be easy.”

But the reality was different.

- Arduino UNO: DEV_ID value did not appear → SPI communication failed

- Raspberry Pi: No signal, no response (MISO)

- FTDI module direct: Code upload worked, but no distance data came out

The issue was not a simple wiring mistake.

Inside the Crowtail module, there was a built-in Atmega328P chip.

This chip blocked communication with external boards and stopped normal operation.

The most serious problem was the lack of official documents.

Pin mapping, firmware structure, and circuit design were not open.

So it was almost impossible to know where the error came from.

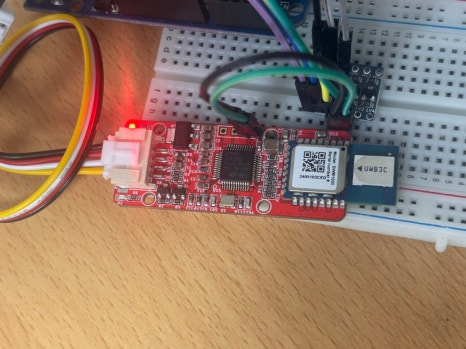

Image provided by customer

In the end, the students learned that using the Crowtail DWM1000 module,

it was impossible to implement proper UWB distance measurement.

They had to find another approach.

🔧 Second Attempt – DIY DWM1000 Soldering

After the first failure, the students decided, “Then let’s solder it ourselves.”

They bought standard DWM1000 modules, soldered them onto a PCB, and tried to connect them with Arduino and Raspberry Pi for distance measurement.

But this process was much harder than expected.

- Module defect: 1 out of 3 modules was broken and did not work at all.

- Communication worked: The other 2 modules connected with SPI communication.

- Distance unstable: But the measured distance was random and not stable.

The root problem was in RF (radio frequency) design.

UWB modules like DWM1000 do not work by simply connecting power and signal wires.

- PCB design: RF signals are sensitive to noise. Even small changes in trace length, width, or spacing can affect them.

- Antenna matching: If the module and antenna are not matched in impedance, the signal can reflect or weaken.

- Power stability: If power noise mixes with the RF signal, distance values become unstable.

In short, with simple DIY soldering, it was impossible to control the RF environment.

So, accurate distance measurement could not be achieved.

📚 The Real Lessons from Failure

These two attempts ended in failure.

But they gave the students very important lessons.

Hardware quality decides the project.

Cheap modules or DIY methods can waste even more time and cost.

The power of documents and references.

Open-source alone has limits.

Official documents and sample codes are needed for fast learning and debugging.

RF technology is not simple.

Unlike Wi-Fi or Bluetooth, UWB RTLS needs accuracy of a few centimeters.

This requires professional design and careful testing.

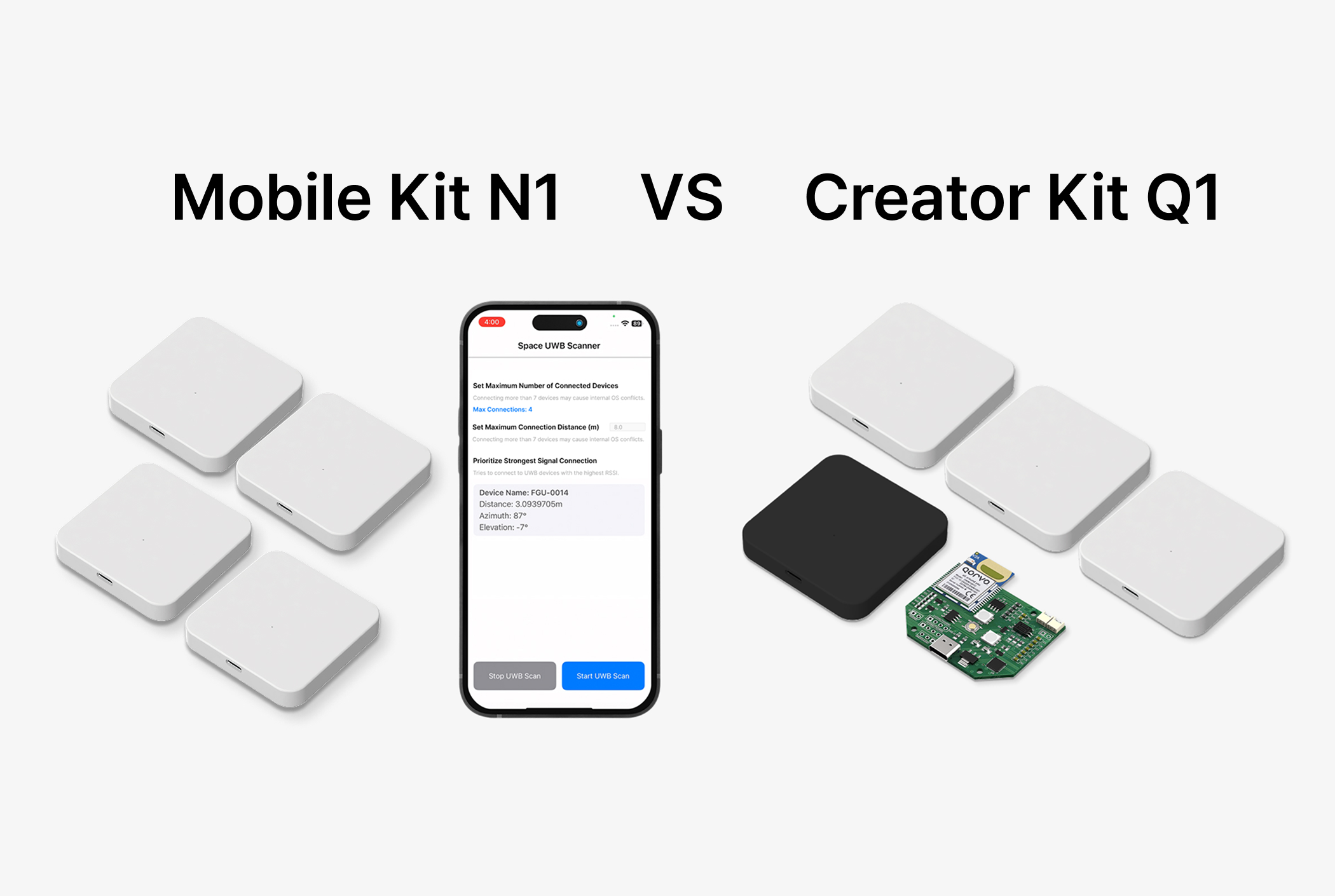

🚀 Choosing the Freegrow UWB Creator Kit

After these trials, the students changed their direction and chose the Freegrow UWB Creator Kit.

- Complete set with tag, anchor, and listener → no soldering needed

- Official manual and sample codes → fast learning possible

- Verified hardware → stable distance measurement data

Thanks to this choice, the project was no longer blocked by hardware issues.

They could move forward to experiments on pedestrian tracking and danger zone alerts right away.

This case is not just a “failure story.”

It carries real lessons that every student preparing for a capstone project should know.

Trying to build UWB RTLS with a DIY approach sounds exciting at the idea level.

But in reality, hardware quality, documentation, and RF design issues make it very hard to succeed.

The students confirmed this themselves.

On the other hand, once they chose a verified commercial kit (the UWB Creator Kit), the project moved to the next level.

They could focus on real applications such as pedestrian tracking and danger zone alerts.

The project grew from just an “experiment” into real “results.”

👉 The goal of a capstone design project is not just to connect hardware.

It is to turn an idea into a complete system and create a result that really works.

The Freegrow UWB Creator Kit can reduce repeated trial and error.

It is a practical choice that helps you turn ideas into experiments and real outcomes faster.

📌 How to Buy

You can get our UWB Creator Kit through Devicemart or by sending a quote request on the Freegrow official website.

Check it out now ▶ [See the UWB Creator Kit]