Hello, this is Freegrow.

In today’s manufacturing environment, everything is digitally connected. Ensuring both productivity and safety is no longer optional—it’s a must. Beyond simple automation, UWB-based RTLS (Real-Time Location System) is emerging as a key competitive advantage.

In this post, we will share how our UWB-based RTLS solution is already being deployed in large-scale manufacturing sites, transforming production line monitoring and smart logistics management.

RTLS: More Than Just Tracking

RTLS stands for Real-Time Location System, a technology that enables tracking of people, assets, and equipment with high precision.

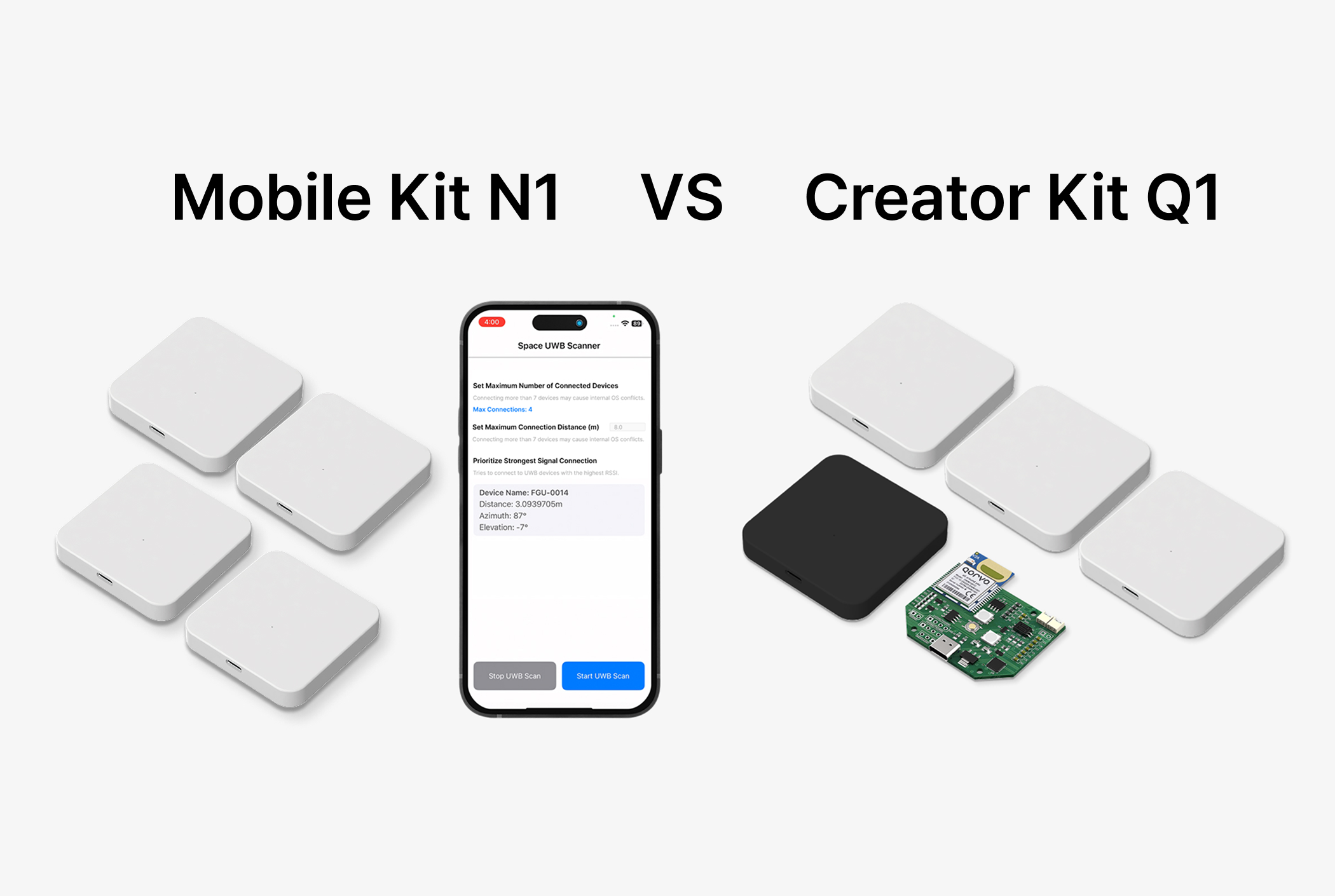

At Freegrow, we developed an UWB-based RTLS system that integrates UWB (Ultra-Wideband), GPS, and RFID, providing 10–30 cm accuracy even in complex industrial environments.

This technology doesn’t just “pin” objects on a map—it makes operations smarter by enabling:

- Tracking products across production stages

- Identifying equipment locations in real time

- Alerting managers when workers enter restricted zones

With these capabilities, factories can prevent accidents, minimize downtime, and eliminate inefficiencies.

Case Study 1 – Precision in Production Line Monitoring

Our solution is currently deployed in a major Korean manufacturing group.

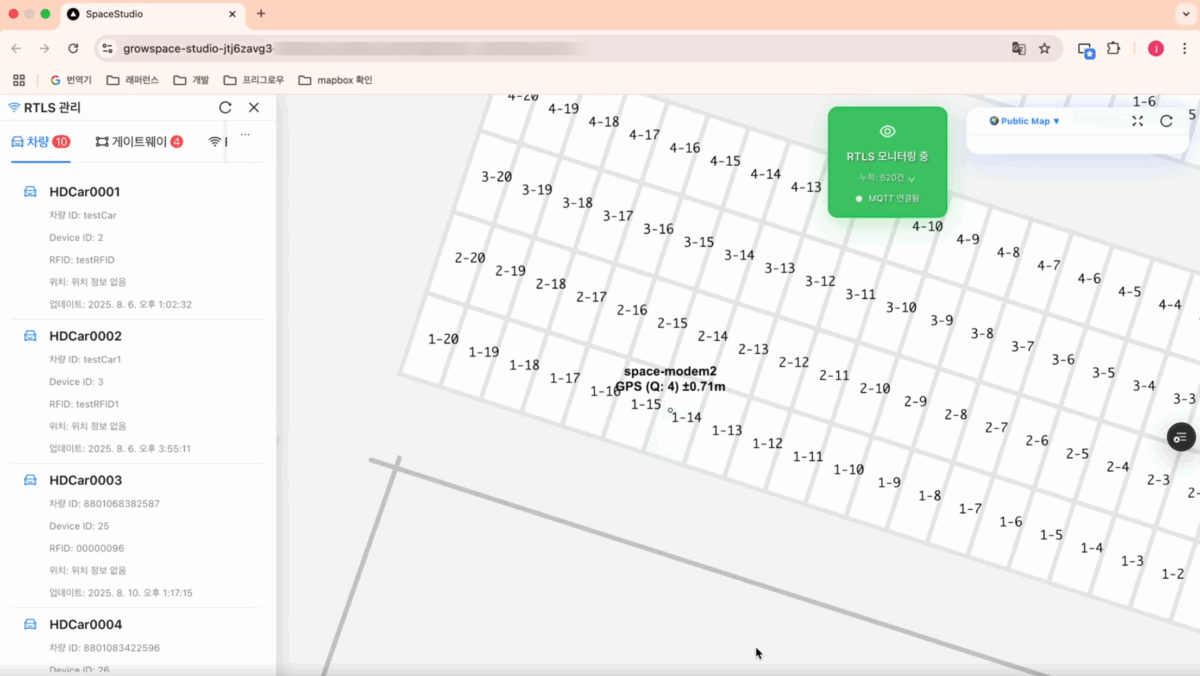

Each product is tagged with an RFID/UWB sensor, and Anchors installed across the production floor record the movement path. When delays occur at a specific stage, alerts are immediately sent to managers.

By visualizing production flows in real time, issues such as equipment failures or bottlenecks can be quickly identified and resolved. This complements traditional MES/ERP systems by providing “on-the-ground visibility” that improves productivity and detects quality issues early.

Case Study 2 – Smarter Logistics & Inventory Management

In warehouses, our UWB-based RTLS eliminates the need for manual scanning. With asset tags, managers can instantly check the location of materials on the dashboard.

This allows them to see:

- Which rack contains which materials

- When items were moved in or out

- Where goods are currently located during transit

Connecting logistics with production lines enables predictive inventory management, reducing delays and virtually eliminating material loss.

Why Freegrow’s UWB-based RTLS Is Different

Our solution stands out with:

- High-precision UWB positioning with 10–30 cm accuracy

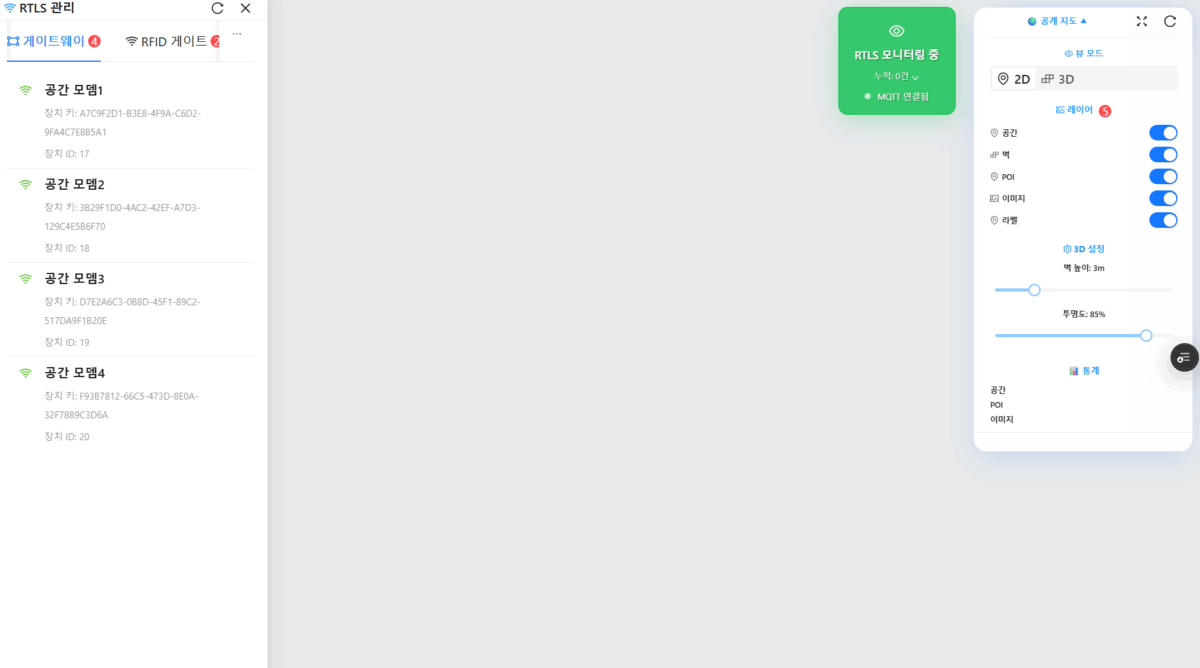

- Indoor/outdoor tracking with GPS integration

- Full RFID compatibility for diverse asset management

- Web-based dashboard with zero installation requirements

- Easy API integration with MES/ERP systems

In short, it’s not just about tracking—it’s about enabling productivity, safety, and visibility at the same time.

Why Enterprises Are Adopting It First

Our UWB-based RTLS is already being rolled out by leading companies in electronics, logistics, construction, and healthcare.

Why? Because RTLS is more than IoT—it’s the foundation of the digital twin for industrial operations. With real-time location data, automation becomes possible, maximizing efficiency, quality, and safety across the board.

And while large enterprises are leading adoption, UWB-based RTLS is equally valuable for SMEs, providing scalable solutions to accelerate digital transformation.

Preparing for the Smart Factory Era

A smart factory is not just about installing new technology—it’s about creating a culture of data-driven operations.

For businesses aiming to evolve into smart factories, UWB-based RTLS should be a key consideration.

At Freegrow, we support every step—from design to deployment and operation—delivering tailored RTLS solutions that fit each client’s environment. If your company is preparing for a smarter factory, now is the perfect time to take the next step.