Hello, this is Freegrow.

In large-scale automotive manufacturing plants, thousands of parts and materials move continuously every single day. On the assembly line, car bodies are assembled; in external warehouses and yards, finished vehicles and parts are constantly entering and leaving. In such a complex environment, it is never easy to answer critical questions in real time, such as “Where is the part I need right now?” or “Are the vehicles waiting for shipment being managed properly?”

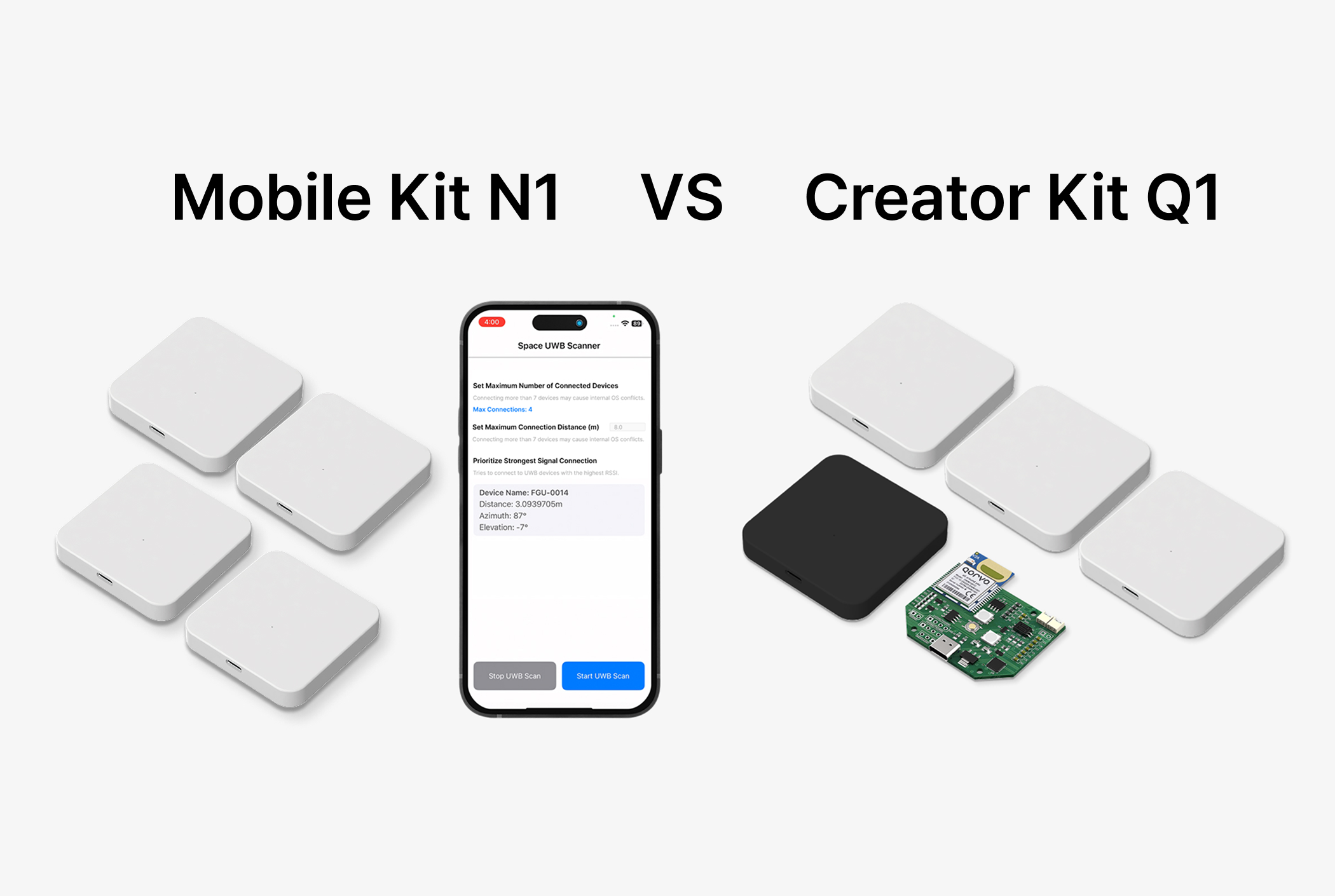

Enterprise Company A faced the same challenge. To solve it, Freegrow introduced a UWB-based RTLS (Real-Time Location System) combined with map creation services. Today, we share how this system transformed their production line monitoring and smart logistics operations.

Why Coordinates Alone Are Not Enough – The Role of Map Creation

While UWB-based RTLS delivers precise X and Y coordinates, raw numbers alone cannot tell you whether that point represents a finished vehicle parking lot, a shipment waiting zone, or a parts warehouse.

That is why Company A integrated map creation. By standardizing spaces such as parking rows, shipment zones, and racks into a GeoJSON-based factory map, the RTLS data could be interpreted visually on the map. From then on, managers no longer looked at spreadsheets of coordinates—they viewed the “picture of the factory” in real time.

Creating a Full Factory Map: SpaceStudio & GeoJSON Standardization

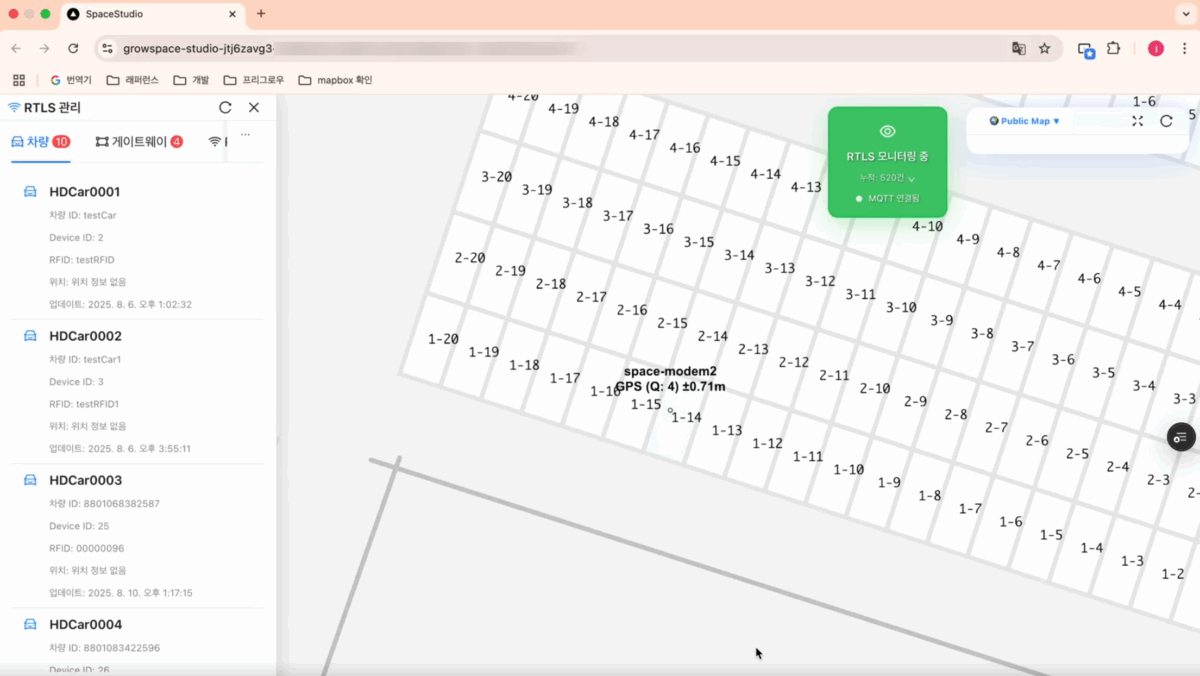

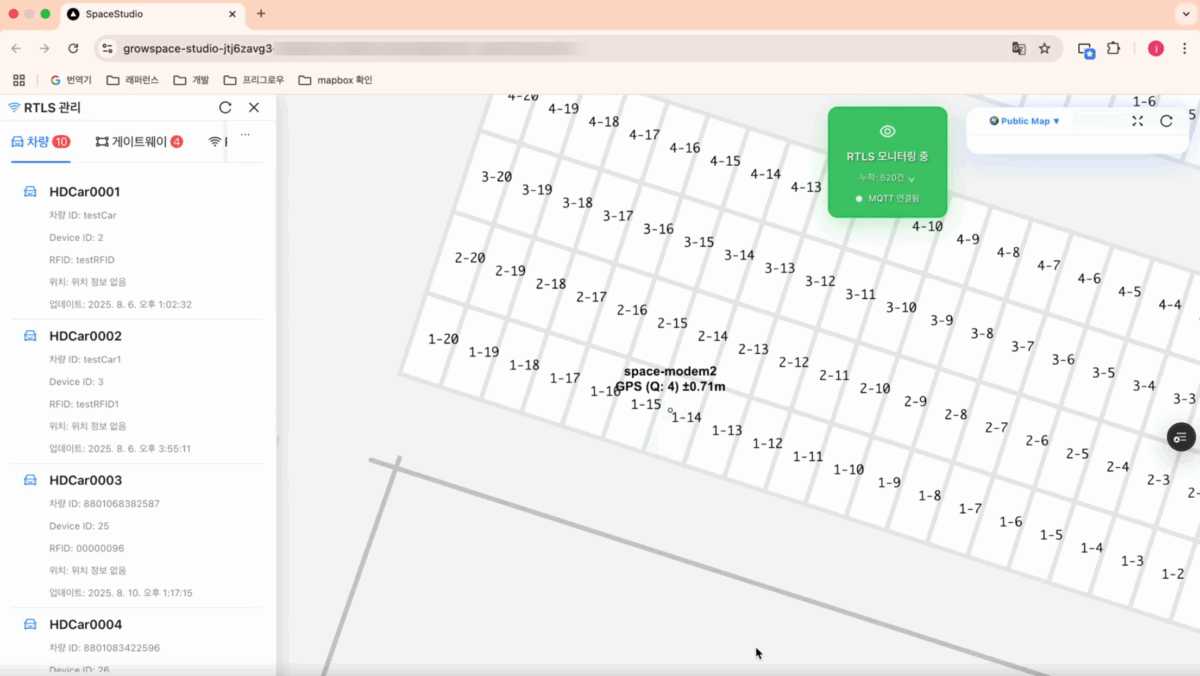

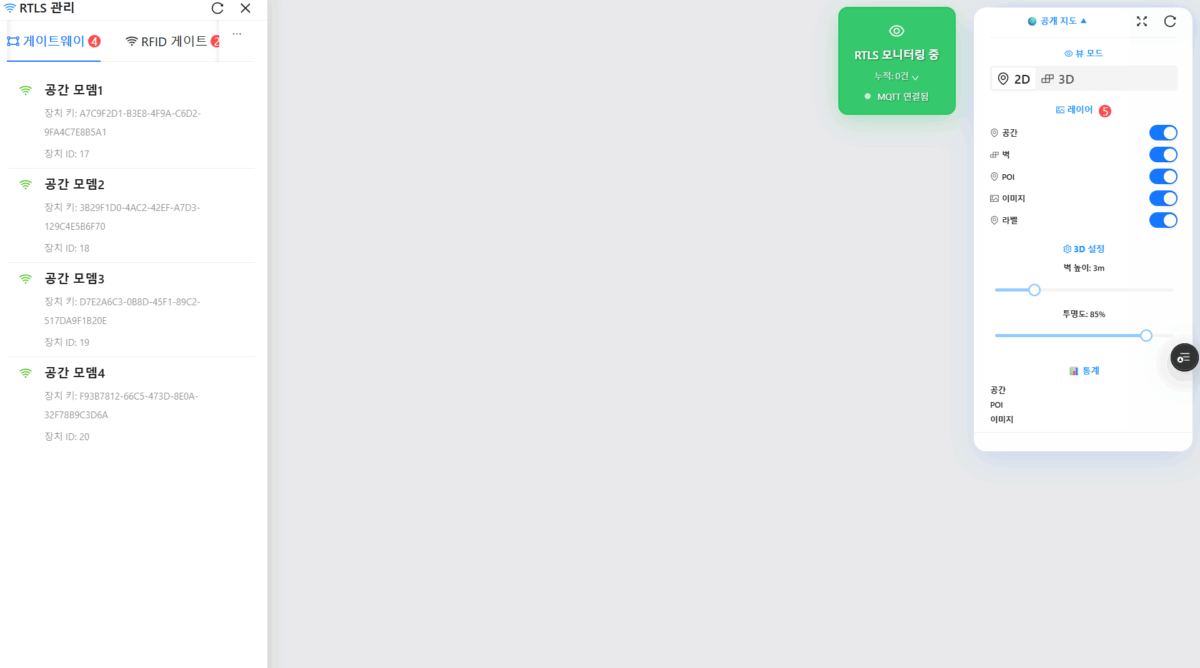

Freegrow used SpaceStudio to create a digital map that clearly separated indoor and outdoor areas of the plant.

- All spatial data was structured in GeoJSON format for RTLS integration

- Internal assembly lines, external parking lots, and shipment zones were defined in detail

- The map can be reused in future smart factory or logistics system expansions

In other words, map creation was not an optional add-on—it was the foundation that made RTLS data usable on the factory floor.

UWB-Based RTLS with Map Visualization: Production Line Monitoring & Smart Logistics

Once the map was complete, Company A could finally visualize real-time RTLS data on the map:

- Parts flow tracking from warehouses to assembly lines (delays and detours immediately visible)

- Shipment yard monitoring, showing exactly which parking line each finished vehicle occupied

- Zoom in/out capability to see both detailed points and the overall flow, enabling flow optimization

This integration allowed managers to trace root causes instantly and manage safety, quality, and delivery schedules simultaneously.

Operational Improvements After Map Creation

After combining RTLS with map creation, Company A saw dramatic improvements in efficiency:

- Production line monitoring: part and vehicle location confirmation reduced from 15 minutes → under 1 minute

- Logistics management: bottlenecks and unnecessary travel routes immediately identified

- Inventory control: fewer missing or excessive stock issues, with real-time visibility

Most importantly, delays caused by missing parts or vehicle location confusion were greatly reduced. This was possible because RTLS hardware was paired with map visualization, not deployed alone.

RTLS Without Maps Is Like a Compass Without Direction

Many enterprises are evaluating RTLS technology. But Company A’s case reveals a simple truth:

RTLS without maps is like a compass without direction.

When accurate factory maps are overlaid with RTLS data, the flow of parts and vehicles becomes instantly clear. Bottlenecks and delays are exposed, enabling faster responses.

For Company A, the first step was not the newest devices—it was digitizing the factory into a map. That map turned RTLS from a location-tracking tool into a comprehensive platform for smart logistics and shipment management.

Now Is the Time to Prepare for Smart Factories

- How efficient are the flows of vehicles and parts in your factory or warehouse?

- What would change if you could see that data on a map in real time?

Building a smart factory is not just about installing devices. The real goal is to create a data-driven culture of operations that makes the shop floor smarter and safer.

At Freegrow, we support every step from design to deployment and operation, offering customized UWB-based RTLS systems and map creation services.

If you are preparing for a smart factory, now is the right time to consider adoption.